From pv magazine Global | via the mobility rEVolution

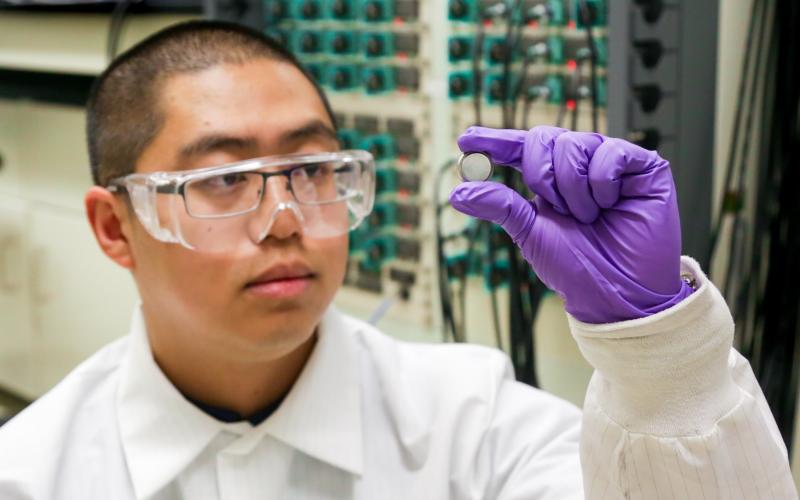

The US Department of Energy’s Oak Ridge National Laboratory and the University of Tennessee, Knoxville, have collaborated the development of a novel fast-charging battery anode material via a scalable synthesis method. The researchers said in a recent paper in Advanced Energy Materials that a novel compound of molybdenum-tungsten-niobate (MWNO) with fast rechargeability and high efficiency could potentially replace graphite in commercial batteries. They focused on a problem that graphite anodes encounter during the charging process, when the electrolyte decomposes and forms a buildup on the anode. This buildup slows the movement of lithium ions and can limit battery stability and performance. “Because of this sluggish lithium-ion movement, graphite anodes are seen as a roadblock to extreme fast charging. We are looking for new, low-cost materials that can outperform graphite,” said ORNL postdoctoral researcher Runming Tao. The Department of Energy’s extreme fast-charging goal for EVs is set at 15 minutes or less to compete with refuel times on gas-powered vehicles – a milestone that has not been met with graphite. “This material operates at a higher voltage than graphite and is not prone to forming what is called a ‘passivation solid electrolyte layer’ that slows down the lithium-ion movement during charging. Its exceptional capacity and fast-charging rate, combined with a scalable synthesis method, make it an attractive candidate for future battery materials,” said Tao.

General Motors and EV battery developer OneD Battery Sciences have signed a joint R&D agreement focused for the potential use of OneD’s silicon nanotechnology in GM’s Ultium battery cells. GM Ventures and Volta Energy Technologies also participated in OneD’s Series C funding round, which the company recently closed at USD 25 million ($39m). The focus of the collaboration is OneD’s SINANODE platform, which adds more silicon onto the anode battery cells by fusing silicon nanowires into EV-grade graphite. Silicon can store 10 times more energy than graphite but most attempts to include more silicon in the anode faced challenges of silicon expansion and breakage. “This limited the amount used to extremely small percentages and only modest performance improvements,” OneD said. “Being able to add larger amounts of silicon – efficiently – is the essential breakthrough needed to produce competitive EVs that meet market demand for high-performance, affordable vehicles.” Under a licensing business model, GM will tap OneD’s 15-year, 240-patent track record, with a focus on increasing energy density and reducing the cost of future GM EV batteries. “GM designed Ultium to be a supremely flexible platform so we can continuously improve our cells as battery technology advances,” said Kent Helfrich, GM CTO, vice president of GM R&D. GM will scale its Ultium EV Platform to 1 million units of annual EV production capacity in North America by 2025. Earlier this year, GM’s first joint venture battery plant with LG Energy for Ultium Cells began production in Ohio, with two additional US plants now under construction and a fourth in the planning stage.

Volvo has unveiled it first electric vehicle with bidirectional charging. Its upcoming all-electric flagship SUV EX90 will support both V2G and V2H applications, so car owners will be able to decide whether to keep their electricity to power their homes or send it back to grid. The EVs will also operate as vehicle-to-load (V2L) battery storage systems. “With the Volvo EX90 you can power your life,” said Olivier Loedel, Volvo’s head of electrification ecosystem. “You could use its battery in many ways, from topping up your electric bike when you’re out and about, to hooking up an outdoor cooking appliance for your weekend camping trip. It could even power your house during the expensive peak hours of the day.” Volvo sees potential to pool EVs in virtual power plants to relieve strain on the grid and cover short periods of instability. But not all of those features and capabilities will be available in all markets, it said. “The bi-directional charging offer will initially be launched in selected markets,” said the carmaker. “We are currently investigating which use cases we will be able to offer in different markets.”

Shoals Technologies has achieved UL Standards certification for its first set of aboveground eMobility charging solutions. The listed products include its Fuel Power Center, Big Lead Assembly (BLA) for DC or AC power, raceways and quick connect bases for chargers. Shoals, a major provider of balance-of-system equipment for solar and energy storage projects, claims its system to lay cables and wires above the ground could help slash 20% of 40% off the cost of typical EV charger installations.

The European Parliament’s Transport Committee has adopted a draft negotiating mandate on the deployment of alternative fuels infrastructure on main EU roads. The draft aims to accelerate the expansion of the EV charging and H2 refuelling infrastructure. It wants electric charging pools for cars to be deployed at 60 kilometres intervals along major European roads by 2026. Among other proposals, the draft calls for two truck charging stations per parking place from 2028 instead of 2031, as proposed by the commission.

Hyundai and Australia’s Ampol have announced plans to expand opportunities for hydrogen infrastructure and battery EVs. Hyundai EV drivers will pay less to charge their cars at Ampol stations across its growing AmpCharge network, along with potential bundled energy offers incorporating home charging and other energy solutions. Ampol recently opened its first sites under the AmpCharge banner, marking the start of an initial rollout of 120 EV fast-charging sites at Ampol stores by the end of 2023. The companies will also collaborate on integrated solutions for fuel cell electric vehicles powered by hydrogen. They said they will also explore the development of hydrogen infrastructure and fleets.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.